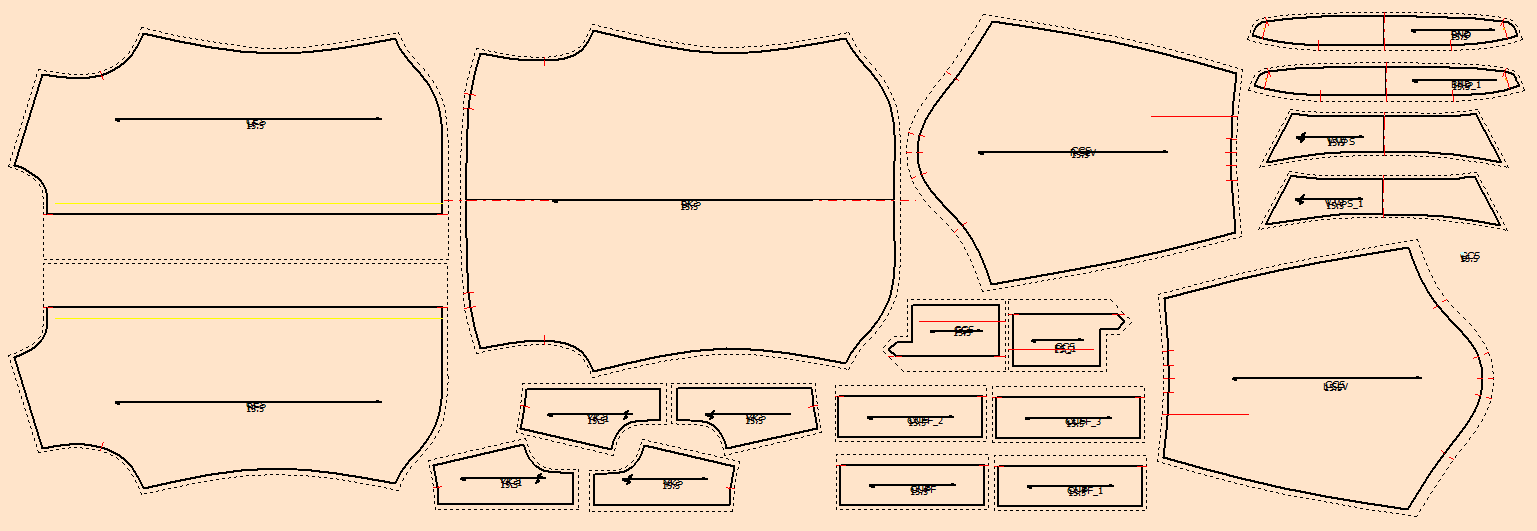

Our shirting process begins with 18 detailed measurements, and a magnitude of styling options like Fit, Fabric, Collars, Cuffs, Pockets, and Monogramming, amongst other available options. These measurements and options are then translated into a digital pattern. This process requires the knowledge and experience of our Master Shirtmaker Fernando Cesário. Using specialty CAD software he designs the pattern to the clients exact size and specification. Once design is finished, it is plotted and moved onto the cutting table.

The cutting process is completely manual. The fabric is laid out over the cutting table and inspected for defects. Using tools of the trade the fabric is hand cut using the plotted patterns. Once cut, the fabric is tagged with the order information and handed to sewing...

The sewing process is a very complex part of custom shirt making. Using only the best quality materials to provide the highest level of quality our Master Tailor Cristina Cesário works with stitch tolerances as low as 1/32 of an inch. This painstaking process is done with much patience to achieve the cleanest, and softest seams in the industry. Button holes & buttons are next...

Button holes are applied by a high precision button hole machine fine tuned for perfect stiches by our team to meet our high standards. The quality does not stop there. Our high speed electronic button sewer attaches buttons in various stitching patterns along with the clients choice of buttons. Super durable buttons are standard and other high quality options such as 3MM M.O.P., Trocas Shell, and Horn buttons are also available. Once finished the shirt goes through a thourough inspection process. And off for pressing...

During pressing, the shirt is carefully handled and pressed at exact temperatures using industrial ironing systems. The shirt is then optionaly folded, x-pinned and packed or hung on the rack as per our clients request.